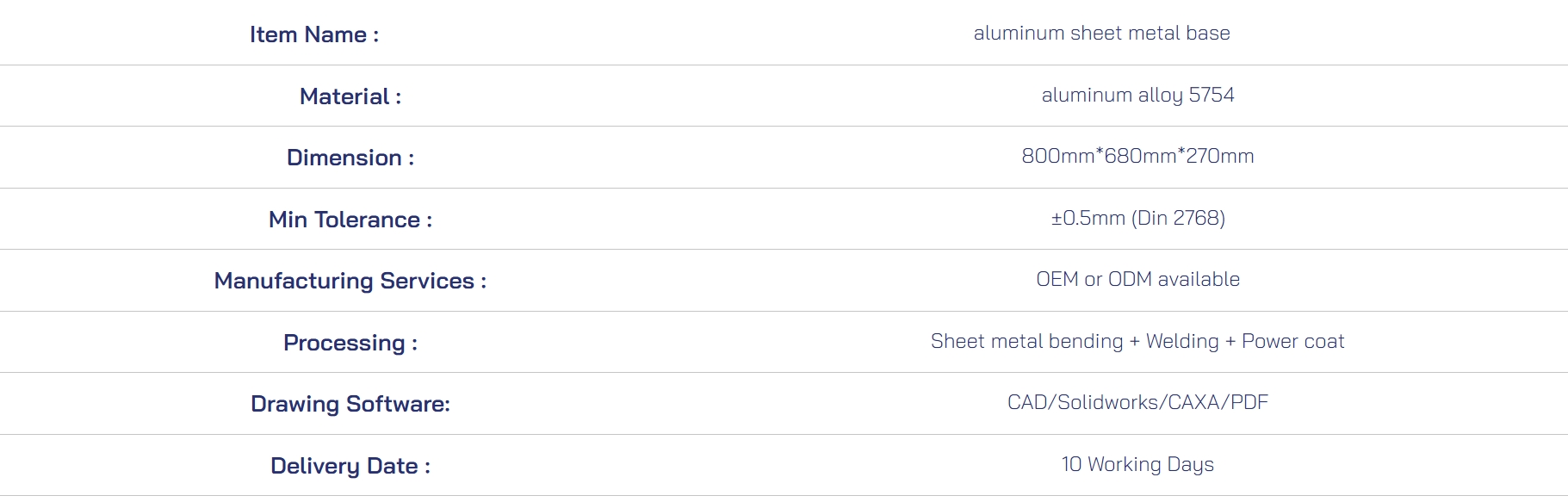

Custom Aluminum Sheet Metal Base

As robotics applications and technology continue to evolve, more and more fields are developing robots that can only be robotic, a base for an intelligent probe robot for mounting tracks and upper manipulation systems.

5754-T5 aluminum alloy plate is selected by bending and welding, and the surface is powder coated black matte (Ral 9005).

Introduction of CNC Machining Parts

Custom Aluminum Sheet Metal Base Manufacturer

Formtechsolution provides custom sheet metal base services to the industrial, food manufacturing, medical industry, military, new energy and other industries. We have specialized in custom sheet metal bases for over 20 years and have extensive fabrication experience and technical knowledge.

We specialize in providing fabrication solutions for many types of metal bases, including: stainless steel, aluminum alloys, copper alloys, carbon steel, galvanized steel, titanium alloys, and more. The customized multi-functional metal base products have many advantages and features such as excellent weather resistance, corrosion resistance, chemical resistance, airtightness, dust resistance, impact resistance, high load, light weight and so on.

In addition, we can also customize various artistic surface coatings and high level metal polishing/brushing for different applications, showing the unique charm of metal texture, and printing corporate logos on the surface according to your promotional needs.

If you need a customized sheet metal base, please contact our expert team.

We will provide one-stop customized production service and cost-competitive factory quotation according to your needs.

About This Metal Base Project.

Formtechsolution was involved in the development and manufacture of the base for the probe robot, commissioned by an intelligent robotics company from Australia. With medium strength, good corrosion resistance, weldability and easy processing and molding, it is a typical alloy in the Al-Mg system. It can better carry the robot’s main operating equipment and detection instruments. It is also strong enough to withstand the impact of the tracks traveling in different terrains.

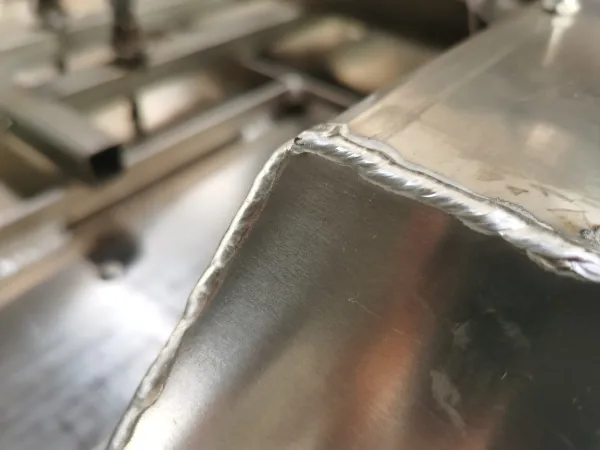

The whole base adopts bending and welding, which can enhance the structural strength and avoid the material breakage after a lot of bending. Moreover, the aluminum alloy 5754 has good oxidation resistance and corrosion resistance, which can maintain a long service life in harsh environments. The surface is powder coated in matte black to enhance the product’s visual appeal as well as its resistance to chemicals.

Customized welding fixtures were used to ensure that all structures were welded together quickly and accurately, and that dimensions were within design tolerances.

Formtechsolution was involved in the design of the product and made various structural suggestions, such as adding internal reinforcements, improving the mounting of the tire axle, increasing the use of bearings, and other optimizations to reduce manufacturing costs and increase manufacturing efficiency.

About Metal Aluminum Alloy 5052

5754 aluminum alloy has medium strength, good corrosion resistance, weldability and easy processing and forming characteristics, is a typical alloy in the Al-Mg system alloys. Welded structures, storage tanks, pressure vessels, ship structures and offshore facilities, transportation tanks and for the requirements of excellent machinability, excellent corrosion resistance, high fatigue strength, high weldability and medium static strength of the occasion.

Different heat treatment state of 5754 aluminum alloy plate is the automobile manufacturing industry (car doors, molds, seals), the main material used in the can industry. 5754 aluminum plate is widely used in welded structures, storage tanks, pressure vessels, ship structures and offshore installations, transport tanks and for the requirements of excellent machinability, excellent corrosion resistance, high fatigue strength, high weldability and medium static strength of the occasion.

-

Aluminum Al :Remainder

-

Silicon Si :0.40

-

Copper Cu :0.10

-

Magnesium Mg :2.6~3.6

-

Titanium Ti: 0.15

-

Zinc Zn: 0.2

-

Manganese Mn: 0.50

-

Chromium Cr: 0.30

-

Tensile strength σb (MPa): 165~265

-

Typical production process: hot rolled plate reserved 25% ~ 35% of the cold working rate, intermediate annealing, cold rolled thickness of the finished product, stabilized annealing temperature of 140 ℃ ~ 150 ℃, holding time 1h.

Supro MFG has a large material warehouse

Metal Base Material Solution

With our extensive experience in custom sheet metal fabrication and our advanced equipment.

We can handle precision sheet metal fabrication projects for any industry.

Galvanized Steel Metal Base

Stainless Steel Base

Carbon Steel Metal Base

No design files? Let Formtechsolution do it for you.

We often come across clients who have no professional design drawings and documentation, only a creative idea, which leads to the project being at a standstill.

If you are in this situation, then contact our team of experts.

Formtechsolution, as an industry-leading custom metal fabricator, has an ever-experienced team of engineers who utilize their extensive fabrication experience and technical expertise to build your idea into a real product and create design files such as STEP/STP/SLDPRT/DXF/PDF/PRT/DWG/AI.

That’s what makes Formtechsolution so great, and 2,000 corporate, entrepreneurial, artist, and other purchasers from around the world enjoy working with us and benefiting from our one-stop manufacturing services.

Custom Metal Base Fabrication Services

With our extensive experience in custom sheet metal fabrication and our advanced equipment.

We can handle precision sheet metal fabrication projects for any industry.

Metal Laser Cutting

Metal Bending

Metal Welding Fabrication

Metal CNC Machining Services

Metal Fittings Assembly

Metal Surface Treatment

China Formtechsolution

Custom Metal Base Parts Design Services

Whether your next project is a metal enclosure project for a precision instrument or a simple storage container, industry-leading design and manufacturing experience is an essential element of the design effort.

Surface treatment of metal brackets

Formtechsolution will choose the right materials, accessories, manufacturing process, etc. according to your needs and application. At the beginning of custom metal bracket projects, all fabrication details will get your permission. Helping you to complete your project with the easiest and most efficient way.

Powder Coating

Effectively wraps metal surfaces and resists rust with aesthetically pleasing custom colors.

Anodic Oxidation

Forms an oxide film on the surface of aluminum alloy to improve hardness, aesthetics, and corrosion resistance.

Brushed Polished

It presents a glossy metallic texture with an even grain that enhances the aesthetics of the product.

Cleaning the metal surface, presenting a uniform roughness and improving the adhesion of the paint.

Mirror Polishing

The metal surface is polished and honed to give a mirror-like finish, increasing the aesthetic effect of the part.

Electroplated

A metal protective film, improve wear resistance, conductivity, reflectivity, corrosion resistance and enhance the role of aesthetic.

Laser Engraving

Commonly used for engraving on the surface of parts, logos, product descriptions, or complex patterns.

Printing paint onto the surface of a product creates content of any shape and color that is hard-wearing and beautiful.

FAQ

Formtechsolution takes buyers' requests and inspirations very seriously. A fantastic idea will ignite our work and actively respond to all demanding requirements and complex product designs.

Is Formtechsolution a manufacturer or a trader?

Formtechsolution is a professional Chinese sheet metal manufacturer, we specialize in the design and manufacture of custom sheet metal parts fabrication and Sheet metal Prototype, ISO 9001-2015 certified, providing a full range of sheet metal parts fabrication solutions and technical support .

We are not a trader, all products are done in our in-house factory, we have a reliable supplier of surface treatment, heat treatment, and standard parts to support us, and we can provide you with economical sheet metal manufacturers ex-works prices.

Do you have your own factory?

We have our own sheet metal fabrication factory, welding workshop, laser cutting workshop, and precision CNC Machining workshop, with a total area of more than 3000 square meters, with 12 technical engineers, 36 skilled workers, 6 quality engineers, and a professional English sales team.

Can I sign a non-disclosure agreement for my product design?

Of course, we keep all the customer's information confidential, sign a non-disclosure agreement, our factory will not allow unrelated personnel to enter without authorization, your product design and patented technology will be protected by us.

I have only one idea and no design files. Can I customize sheet metal parts?

Yes, we have rich manufacturing experience and technical knowledge, can draw professional design files (including: STL/STEP/IGES/PDF/CAD, etc.) according to your ideas, and provide you with free manufacturability solutions. Actively help you optimize product design, reduce costs, and make your product design more dynamic in the sales market.

How to ensure the quality of the product?

From raw materials to finished packaging, we will provide you with reliable quality inspection reports and photos at any time. If you need an authoritative third-party inspection report, we can also actively cooperate to ensure that you will receive high-quality products.

What are the payment terms?

T/T, Paypal western union, L/C, and other channels you suggest (contact us for negotiation).

formtechsolution provide PPAP files?

Yes, we can provide system documentation for PPAP level3.

Why is your offer not the lowest?

Our quotations are all factory quotations from manufacturers, and all manufacturing costs and labor costs are traceable. We all use the raw materials of authoritative manufacturer brands, refuse to cut corners, and all products are subject to our quality control.

While there are plenty of small businesses that offer you a very low price, the quality can be at risk.

What your project needs more is the guarantee of high-quality products and on-time delivery, not high-risk.

Only a small quantity is required, what is the MOQ?

We do not set a minimum order quantity. Whether you need a small amount of prototypes or large quantities, we will treat you equally and provide you with a full range of manufacturing services and technical support.

How to guarantee on-time delivery of products?

We will develop a detailed production plan, every point in time will be practically verified, and all processes are under our monitoring to ensure on-time delivery of high-quality products. (Except for the influence of force majeure factors)

Once there is a signal of delay, we will organize more production capacity to ensure on-time delivery.

More Case Studies

Formtechsolution actively helps customers from design and prototype to mass production of high quality sheet metal fabrication services.

Custom Stainless Steel Water Tanks

Custom Stainless Steel Water Tanks

Custom Stainless Steel Water Tanks

Custom Stainless Steel Water Tanks

Custom Stainless Steel Water Tanks