23 YAERS+

PRODUCTION EXPERIENCE

IN METAL FABRICATION

• Founded in 2002, with 23 years+ experience in Sheet Metal Fabrication & Stamping,

serving over 20+ countries and 3000+ companies

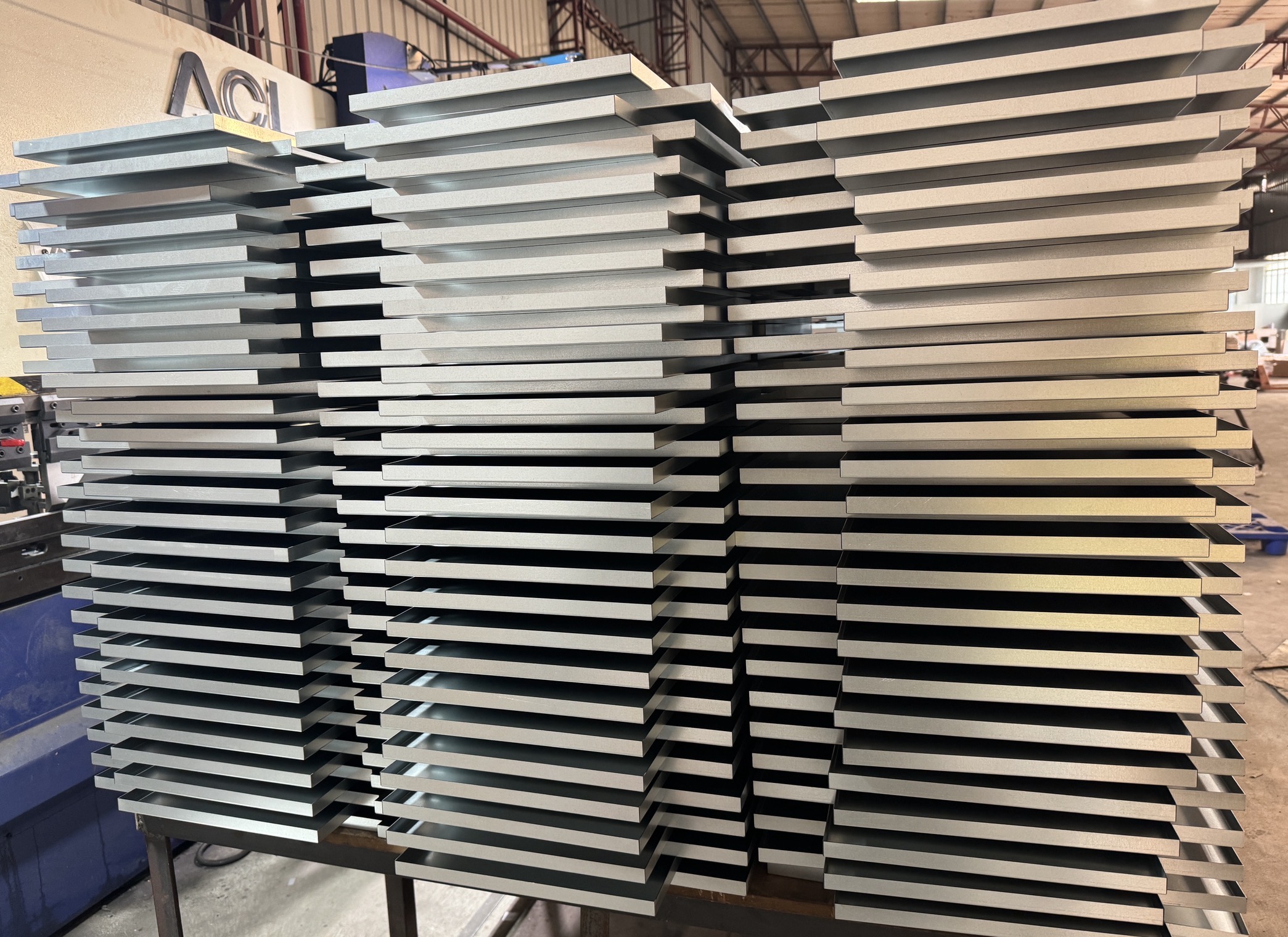

• 7,000 Square Feet of Self Owned Workshop in China

• Capabilities: Stamping、Deep Drawing 、CNC Bending 、Laser Cutting、Welding and more

ISO 9001-2015

Quoted in 24 Hours

7-15 days Rapid Prototype

One-Stop Manufacturing Services

Mould Workshop

Pro Engineer & Serivce Team

Laser Cutting & Bending Workshop

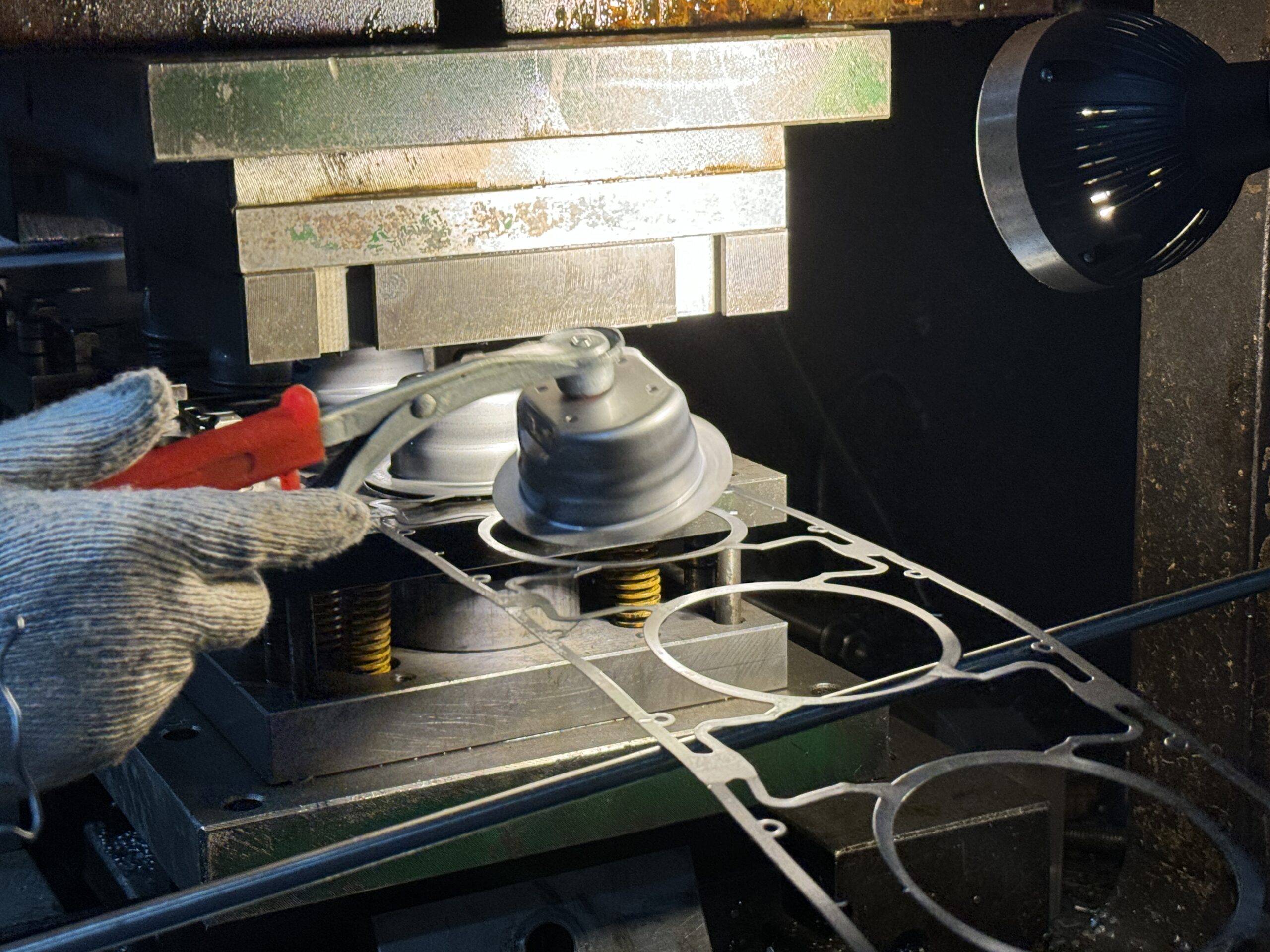

Stamping Workshop

Global Buyers Served

Projects Case

Total Factory Area

Overall Team Staff

Items Our Capabilities

Proudction volume short-run or 10000+ production, and high volume production

Typical tolerance range from +/- 0.05mm-0.2mm

Sample lead time 7-15days

Tooling lead time 10-25 days( depends on project) Stamping molds design in-house in 3 days Stamping molds made in-house in 2 weeks

Production lead time 15-20 days( depends on project)

PRODUCT CATEGORIES

Custom Stainless Steel Water Tanks

Custom metal cases

Custom Stainless Steel Water Tanks

Custom Stainless Steel Water Tanks

Custom Stainless Steel Water Tanks

One-Stop Custom sheet Metal Fabrication Services

Equipment

-

Laser Cutting Machine

- Stamping Press: 10T、15T、25T、40T、45T、60T、80T、100T

- Automatic Stamping Press: 40T、80T、100T、160T、200T

- Hydraulic Press:100T、350T

- CNC Bending Machine

- Lathe Machine

- Milling Machine

- Polishing Machine

- Brushing Machine

Material

- Aluminium

- Carbon Steel

- Stainless Steel

- Cold Galvanized Steel

- Al-Mg-Zn Alloys

- Copper / Brass /Bronze

- Others

Surface Treatment

- Powder Coating

- Anodizing

- Electro Coating

- Trivalent Zinc Plating

- Hot Dip Galvanized

- Passivation

- Geomet

- Dacromet

- Sandblasting

Custom metal boxes

The manufacturing process of forming sheet metal by cutting, bending and other processes, such as panels, brackets and housings.

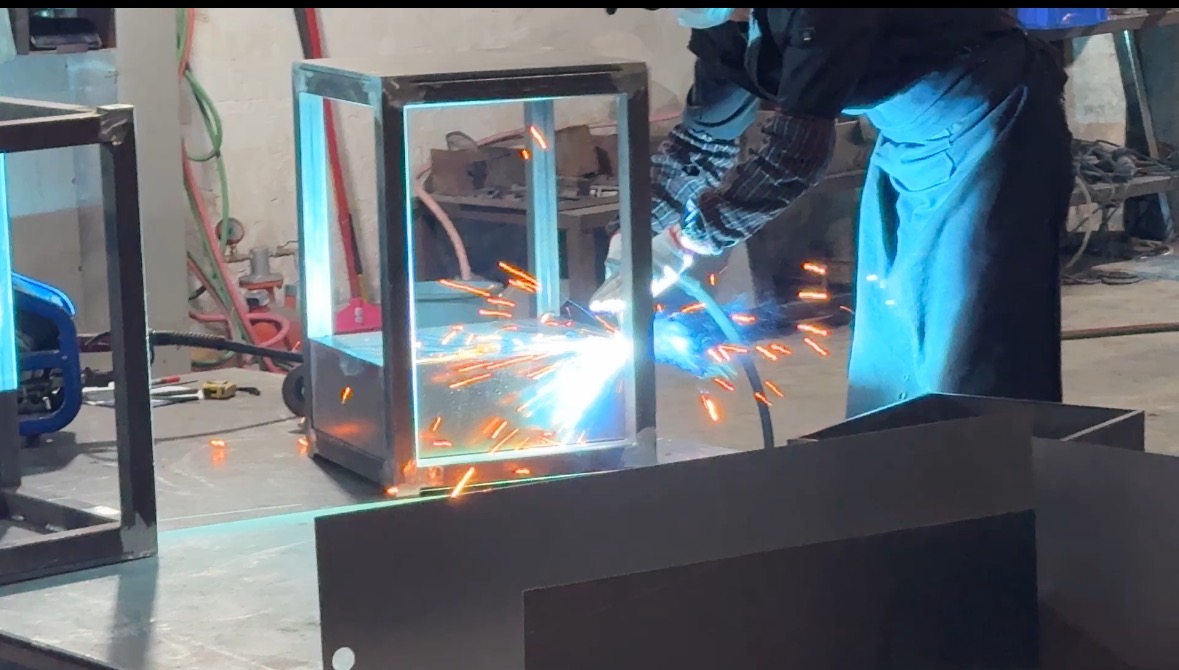

Metal Welding Fabrication

Connect a variety of metal materials by means of high temperature or pressure to obtain a complete assembled sheet metal part. Usually used in pipelines, steel structures, metal cabinets, enclosures, etc.

Customer recognition of us

Ensure high quality products, on time delivery, customer satisfaction, is the purpose of our service.

FAQ

Are you a trading company or a factory?

We are a direct factory with experienced engineers and staff and a workshop area of approximately 7,000 square meters.

Is it possible to know how is my product going on without visiting your company?

We will offer a detailed products schedule and send weekly reports with digital pictures and videos which show the machining progress.

What should we do if there are no drawings?

Please send your samples to our factory and we can copy or provide you with a better solution.

Will my drawings be safe after sending them to you?

Yes, we will save them well and will not be released to third parties without your permission.

What is your lead time?

lt depends on the order quantity and the season you place the order. Typically, samples last for 7-15days weeks and mass production lasts for 15-30 days, can process urgently if needed.

How to ensure the quality of the product?

From raw materials to finished packaging, we will provide you with reliable quality inspection reports and photos at any time. If you need an authoritative third-party inspection report, we can also actively cooperate to ensure that you will receive high-quality products.

What's your after-sale service?

If there is a quality problem, please provide photos or test report, we will replace defective goods or return funds.

Our Resources

Ultimate Guide to Custom Metal Enclosures: How Sheet Metal Bending & Welding Enhance Your Project

Ultimate Guide to Custom Metal Enclosures: How Sheet Metal Bending & Welding Enhance Your Project

Website Online

Websit Online!

Hello world!

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!