Contract Manufacturing

Compound Die Stamping

Compound Die Stamping Services

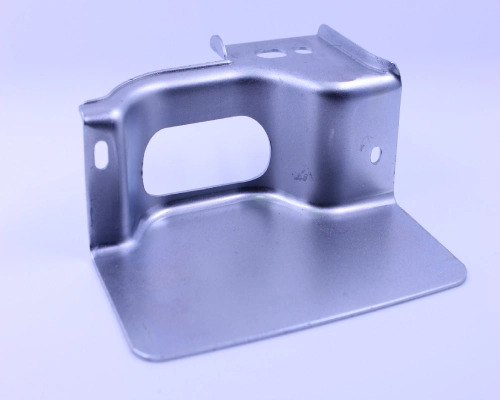

Compound die stamping is a high-efficiency and low-cost precision metal stamping manufacturing process. It is suitable for small and medium-sized metal stamping projects. It can not only ensure the precision tolerances required for part design, but also has a lower manufacturing cost than progressive die molds.

At Formtechsolution, we have a professional compound die stamping production line, with 12 high-speed presses ranging from 10 tons to 340 tons. All equipment is dedicated to running compound die stamping dies. With a professional stamping technology team, it can meet the needs of metal stamping parts in all industries and provide competitive cost quotations from Chinese compound die stamping manufacturers.

We provide a series of precision stamping solutions, including: mold design and manufacturing, product design optimization, DFM manufacturability report, product mass production, welding, surface treatment, heat treatment, packaging, and transportation to the world.

Talk to our mold experts now, to help you create unexpected metal stamping projects faster.

What is Compound Die Stamping

Compound die stamping is a stamping process similar to progressive die stamping, but the difference is that the progressive die has a lot of cavities arranged in an orderly manner on the die, and the material will be shaped by different cavities after being formed by the die. Finally we can get a complete product.

However, Compound dies combines two or more feature forming modules with multiple sliders and mechanical settings. In a stamping cycle, different details of the part are created, such as: cutting blanks, punching, Stretching concave-convex type and deep-drawing molding, etc.

Although it seems that the mold has performed a movement, the ingenious mechanical transmission principle allows all the features to be completed at one time and maintains extremely strong quality stability.

Compound die stamping is very suitable for production orders with limited budgets and small and medium-sized quantities, and can demonstrate very high efficiency and low labor costs, with market-competitive manufacturing technology.

Sheet Metal Stamping Services

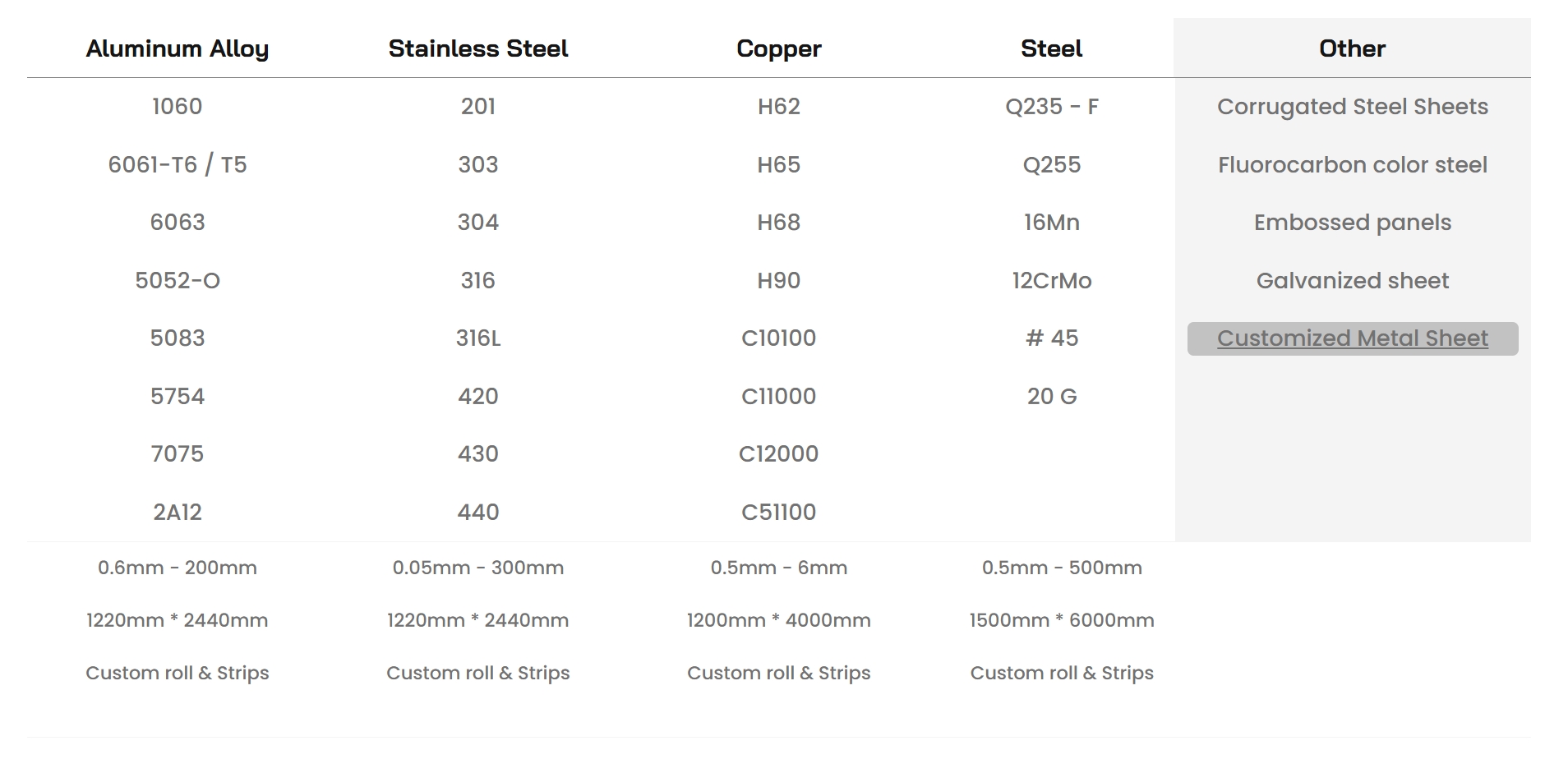

Compound Die Stamping Material Solutions

Formtechsolution offers a robust stockpile of materials to help your products can get up and running with a quick turnaround.

Within an hour, the metal material is ready for the sheet metal bending process.