Custom Carbon Steel Parts

We offer a wide range of custom sheet metal parts fabrication services for numerous projects from rapid prototypes to mass production.

All information is safe and confidential.

About carbon steel

Carbon steel is one of our most commonly used metals. It is an iron-carbon alloy with a carbon content of 0.0218% to 2.11%, also called carbon steel.

Generally, the higher the carbon content of carbon steel, the greater the hardness and the higher the strength, but the lower the plasticity.

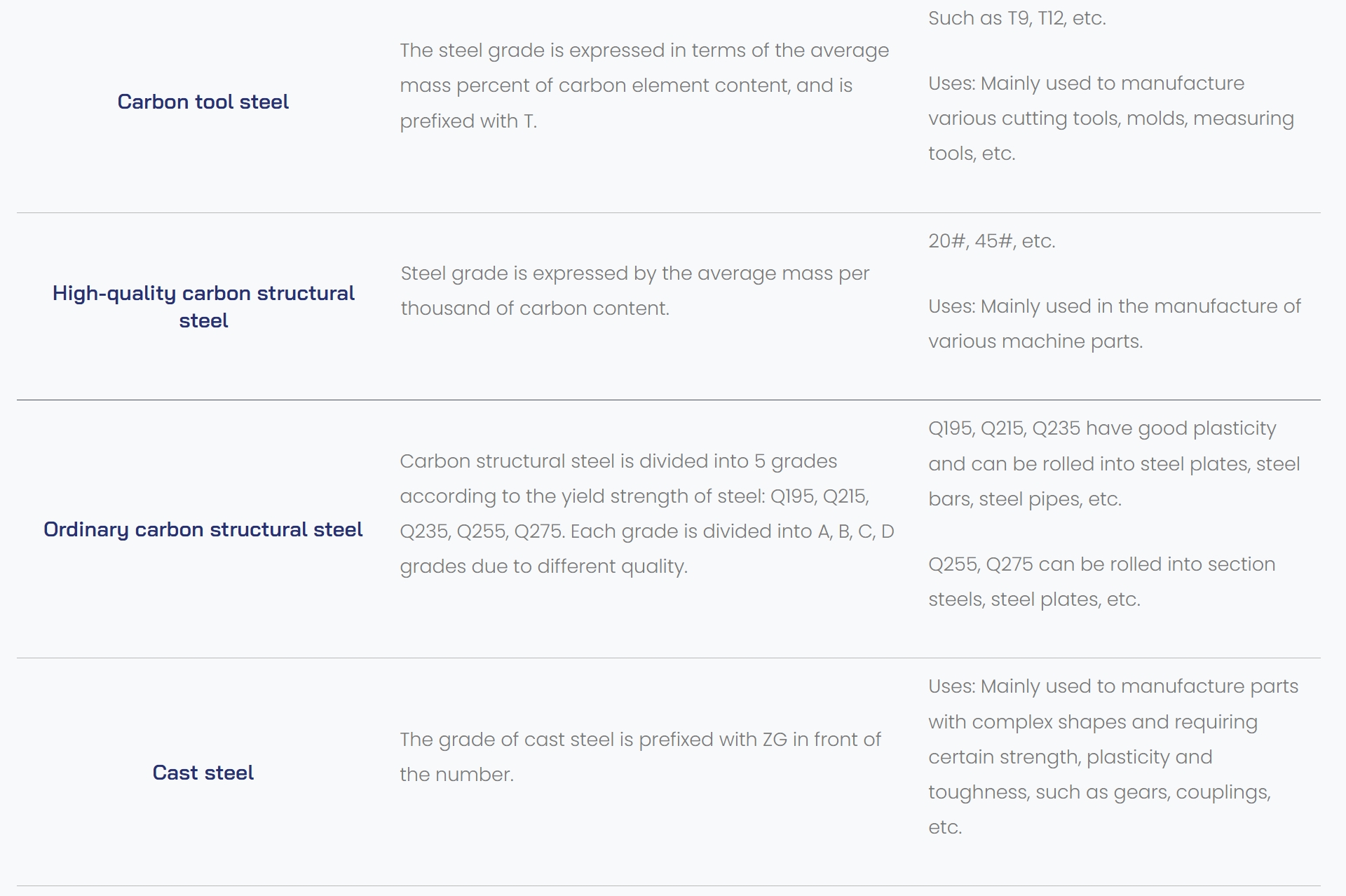

According to the application requirements of different industries, carbon steel is divided into three types: low carbon steel, high carbon steel, and medium carbon steel. Each type of carbon steel has different strength and application industries.

Through bending forming, stamping, milling, cutting, welding, etc., products such as pipes, steel structural parts, chains, screws, boxes, cabinets, standard parts, hammers or screwdrivers can be produced.

Why Choose Formtechsolution

Formtechsolution specializes in the manufacture of customized carbon steel parts for more than 20 years, and has accumulated rich processing experience. It can process high-precision customized carbon steel sheet metal bending parts, customized carbon steel stamping parts, customized carbon steel CNC machining parts, etc. And a series of secondary processing services.

We are good at integrating multiple manufacturing capabilities to deliver high-quality customized carbon steel parts and components one-stop. At the same time, strict tolerance standards are achieved on the shape, surface and size.

Reliable raw materials

100% to ensure that the materials meet the requirements of Rohs and yours. Material certificates and SGS reports can be provided.

Fast and efficient turnover

Reply to the factory quotation within a few hours, and start production today as soon as possible, and send it to the world tomorrow.

Multiple material choices

Steel, aluminum, stainless steel, titanium, engineering plastics, such as PEEK, PC, POM. etc.

Strict quality control

100% quality inspection, comply with ISO 2768-F processing standard tolerances.

Real ex-factory price

Cost-effective factory cost quotation, no intermediary price difference, more cost-effective service.

Active technical support

Actively cooperate at any time to provide manufacturability technical suggestions for changes in customer requirements.

Carbon Steel Style

The most popular performance of stainless steel is corrosion resistance, which reduces the effect as the carbon content increases, so maintaining a low carbon level is one of the main advantages of stainless steel.

Low carbon steel (C: ≤0.25%), also known as mild steel, is easy to accept various processing such as forging, welding and cutting. Commonly used to make chains, rivets, bolts, shafts, etc.

Medium carbon steel (0.25%<C≤0.6%) is divided into ordinary carbon structural steel and high-quality carbon structural steel according to its quality. The hot working and cutting performance of medium carbon steel is good, but the welding performance is poor. Strength and hardness are higher than low carbon steel, while plasticity and toughness are lower than low carbon steel. Hot-rolled and cold-drawn materials can be used directly without heat treatment, or they can be used after heat treatment.

The quenched and tempered medium carbon steel has good comprehensive mechanical properties. Therefore, among the various uses of medium strength level, medium carbon steel has achieved the most extensive application. In addition to being used as a building material, it is also widely used in the manufacture of various mechanical parts.

Medium carbon steel (0.25%<C≤0.6%) is divided into ordinary carbon structural steel and high-quality carbon structural steel according to its quality. The hot working and cutting performance of medium carbon steel is good, but the welding performance is poor. Strength and hardness are higher than low carbon steel, while plasticity and toughness are lower than low carbon steel. Hot-rolled and cold-drawn materials can be used directly without heat treatment, or they can be used after heat treatment.

The quenched and tempered medium carbon steel has good comprehensive mechanical properties. Therefore, among the various uses of medium strength level, medium carbon steel has achieved the most extensive application. In addition to being used as a building material, it is also widely used in the manufacture of various mechanical parts.

Application of custom stainless steel parts

Reasonable surface treatment of metal parts can improve the durability, corrosion resistance, heat resistance, electrical conductivity and appearance decoration of the material.

Application of custom carbon steel parts

-

Increase strength

-

Increase carburizing capacity

-

Low cost metal

-

Fully recyclable and reusable for sustainable processing