Custom Aluminum Alloy Parts

Formtechsolution has focused on custom aluminum alloy parts for more than 20 years. There is no minimum order quantity limit, high-efficiency rapid prototyping, and a real Chinese manufacturer’s quotation.

Get to know us, browse more about the aluminum alloy product list.

All information is safe and confidential.

Metal Enclosures Manufacturer

Aluminum alloy material is based on pure aluminum, mixed with some metal elements to form a light, non-magnetic metal material. The density of aluminum alloy is 2.63~2.85g/cm3, and it has high strength (σb is 110~650MPa ), is widely used in various industries.

In the past 100+ years of industrial applications, a variety of aluminum alloys can be formed by adding different metal components, with special properties such as light weight, thermal conductivity, easy welding, corrosion resistance, and chemical resistance.

Because of its good processing performance, high strength and flexible surface treatment, customized aluminum alloy parts are widely welcomed. Aluminum alloy is a low-cost material for custom metal parts and prototypes, whether it is mass production or rapid metal prototyping.

Strong ability to

custom aluminum alloy parts

Our in-house manufacturing equipment can provide customized aluminum alloy parts solutions such as sheet metal fabrication, sheet metal bending, sheet metal stamping, welding fabrication, and sheet metal prototype.

We have focused on customizing aluminum alloy parts and rapid prototyping for more than 20 years. Professional manufacturing technology can efficiently create the parts required by customers and maintain the original performance of aluminum alloy on the basis of meeting all quality requirements.

We refuse to cut corners and accelerate the advancement of aluminum alloy parts manufacturing projects for all customers with economical factory prices and world-class quality standards.

-

On time delivery

-

Rich experiences

-

Professional technical knowledge

-

Advanced internal manufacturing equipment

-

Complete manufacturing capability

-

Real manufacturer factory price

Custom Aluminum Alloy Parts

Material Solutions

1xxx: 1050, 1050A, 1060, 1100

1××× series: pure aluminum (aluminum content is not less than 99.00%)

Formability and surface treatment are good, and its corrosion resistance is the best among aluminum alloys. The higher the purity, the lower the strength. Daily necessities, aluminum plates, lighting appliances, reflectors, decorations, chemical industry containers, heat sinks, melted wires, conductive materials.

2xxx: 2014 2017 2024

2××× series: aluminum alloy with copper as the main alloying element

Contains a large amount of Cu, poor corrosion resistance, but high strength, can be used as a structural material, forged products can also be used, aircraft, gears, oil, pressure components, wheel and axle.

3xxx: 3003, 3004, 3005, 3105

3××× series: aluminum alloy with manganese as the main alloying element

Formability, weldability, and corrosion resistance are all good. General utensils, heat sinks, makeup boards, photocopier drums, and ship materials have excellent formability and good corrosion resistance. Aluminum cans, light bulbs, roof panels, colored aluminum panels

5xxx: 5005, 5052, 5754, 5083

5××× series: aluminum alloy with magnesium as the main alloying element

5052 is the most representative alloy with medium strength. It has good corrosion resistance, weldability and formability, especially high fatigue strength and good seawater resistance. General sheet metal, ships, vehicles, construction, bottle caps, honeycomb panels, low-temperature vessels, pressure vessels.

6xxx: 6061, 6082, 6063

6××× series: aluminum alloy with magnesium as the main alloying element

6061 heat-treated corrosion-resistant alloy. T6 treatment can have a very high endurance value, but the strength of the welding interface is low, so it is used in screws, anchors, ships, vehicles, and land structures. 6N01 is a medium-strength extrusion alloy with a strength between 6061 and 6063. , Extrudability, stamping and hardenability are all good, can be used as large-scale thin-meat-shaped materials with complex shapes, good corrosion resistance and weldability. Vehicles, land structures, ships

6063 representative extrusion alloy, with lower strength than 6061, good extrudability, can be used as a profile with complex cross-section shape, good corrosion resistance and surface treatment, construction, highway guardrail, high fence, vehicle, Furniture, home appliances, decorations

7xxx: 7075

7××× series: aluminum alloy with zinc as the main alloying element

7075 aluminum alloy has one of the highest strength alloys, but the corrosion resistance is not good, and the covering skin of 7072 can improve its corrosion resistance, but the cost is increased. Aircraft, ski poles 7050 7050 alloy with improved hardenability of 7075, good stress corrosion crack resistance, suitable for thick plates, forged aircraft, high-speed rotating bodies, 7N01 alloy for welding structure, high strength and the strength of the welding part can be placed at room temperature. After returning to the strength close to the base metal. The corrosion resistance is also very good. Vehicles, other land structures, aircraft

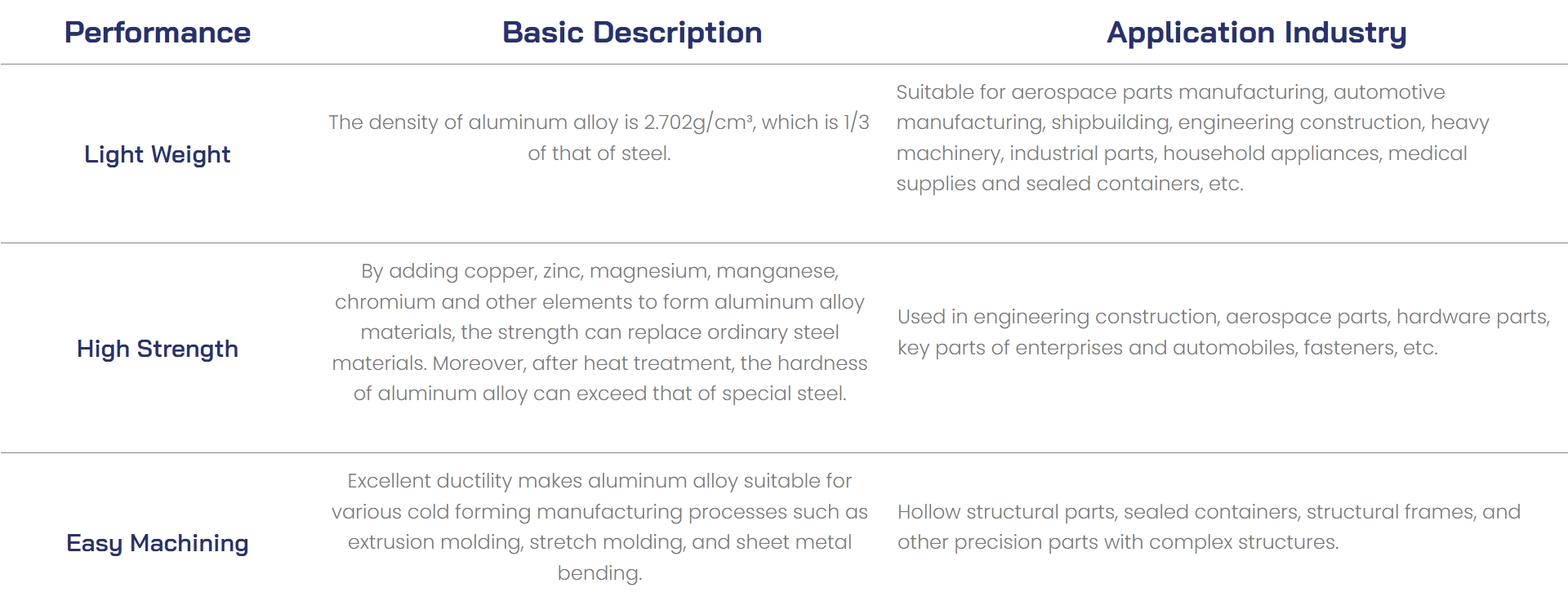

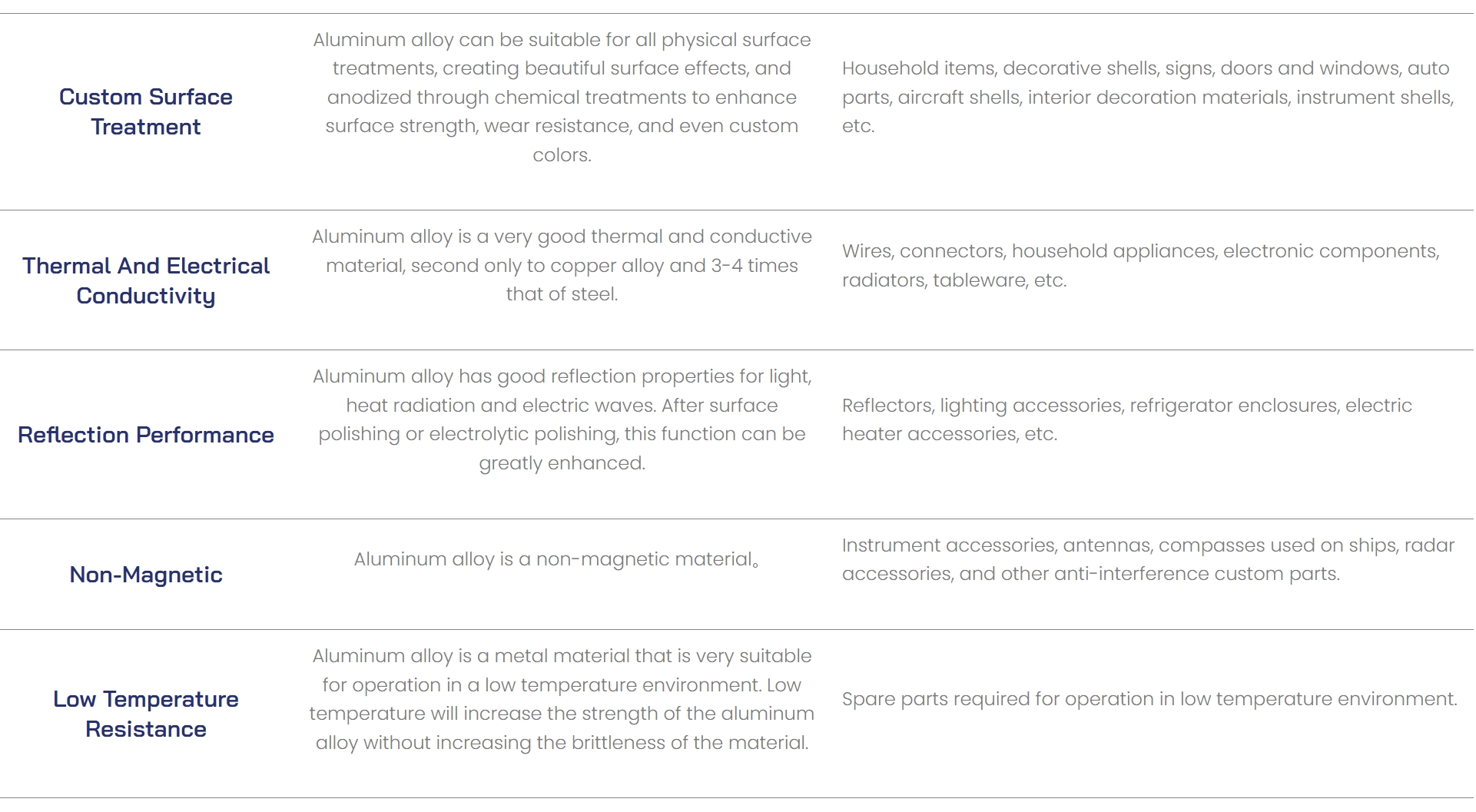

Performance and application industry

Customized aluminum alloy parts have the characteristics of low density, good mechanical properties, good processing properties, non-toxic, easy to recycle, electrical conductivity, heat transfer and corrosion resistance. They are used in the marine industry, chemical industry, aerospace, metal packaging, and transportation. Widely used in transportation and other fields.

-

Good corrosion and chemical resistance

-

Easy processing, high strength

-

Light weight

-

Low cost materials

-

Excellent thermal and electrical conductivity

-

Flexible surface treatment solutions

-

Rich selection of performance alloys