Sheet Metal Stamping

Services

Formtechsolution is a leading sheet metal stamping company in China.

Formtechsolution manufactures complex and high-quality precision stamping parts and components for customers around the global.

Metal Stamping Production Processes

Items Our Capabilities

Proudction volume short-run or 10000+ production, and high volume production

Typical tolerance range from +/- 0.05mm-0.2mm

Material thickness ranges from 0.2mm to 10mm

Sample lead time 7-15days

Tooling lead time 10-25 days( depends on project) Stamping molds design in-house in 3 days Stamping molds made in-house in 2 weeks

Production lead time 15-20 days( depends on project)

Sheet metal stamping services

Professional Contract Manufacturing Services

Progressive die Stamping services

Progressive die stamping is widely used in electronic components and automobile manufacturing industries, which can realize multi-functional stamping operations in the same set of progressive die molds, such as cutting, stamping, punching, stretching and automatic feeding functions.

Deep drawing stamping services

relying on custom deep drawing services, metal sheets can be manufactured into thin-walled parts with cavity structures such as trapezoids, cones, spheres, rectangles, etc., keeping the wall thickness uniform, which is one of the very important sheet metal fabrication processes .

Compound die stamping services

Compound die stamping is a high-efficiency precision stamping process. Integrate multiple stamping processes in the same precision stamping die to create precision stamped parts with complex structures in one stamping process.

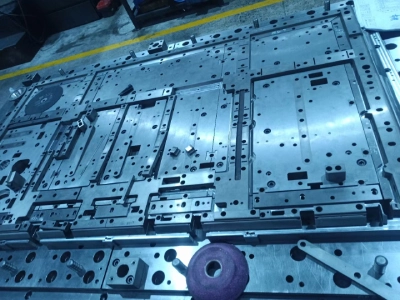

Sheet metal stamping dies & processes

Formtechsolution has a professional in-house stamping die factory, which can reasonably design and manufacture stamping dies according to customers’ product requirements and applications. We have a professional precision stamping die engineering team, providing a full range of stamping die technical support and manufacturing services.

Why Choose Formtechsolution for Sheet Metal Stamping?

Formtechsolution is a leading sheet metal stamping company in China, has been focusing on customized precision stamping parts services for 30 years, with more than 5.000.000 metal stamping parts shipped annually from our 2500㎡ precision stamping base to all buyers worldwide, maintaining an annual production capacity of 1,000 tons.

Contact Formtechsolution now, to learn more about our custom metal stamping services and request a real manufacturer quote.

We are equipped with 80 sets of 6ton-1000ton pressure stamping equipment, which can process materials with a thickness of 0.005 inches to 5 inches, and can manufacture stamping parts with a maximum width of 24 inches.

The largest hydraulic stroke provides cost-effective manufacturing solutions for customized stamping parts of any size.

The internal precision stamping die processing workshop can handle high-precision and complex stamping die design and manufacturing, including: progressive die stamping dies, compound dies, deep drawing dies, precision single stamping dies and rapid stamping tools.

We have a 7*24-hour online metal stamping technical team, and we can get detailed quotation feedback within a few hours. We actively handle all customer parts stamping plans. Within a few hours, the mold or material will start the production plan. The efficient turnover enables us to maintain 95% customer satisfaction, saving customers’ time cost and communication cost.

More than 20 years of customized stamping parts service experience has made our manufacturing process smoother and run all links more efficiently. Ensure timely delivery of high-quality products and fulfill the promises made to customers.

In addition, the professional quality control team can predict human or process errors and make correct corrections in time, so that all links will proceed as planned, and timely delivery will become simple.

We provide the most economical Chinese stamping manufacturer’s quotation, relying on advanced automation equipment to greatly save labor costs, and through a reasonable manufacturing process to reduce the scrap rate to a minimum, have cost advantages in the industry, and help customers truly receive Quotations from Chinese stamping suppliers.

It is worth mentioning that we refuse to cut corners, and all products will be issued with authoritative material reports and physical and chemical performance reports.

With the manufacturing capacity from 1 piece to 1.000.000 pieces, there is no MOQ limit, helping customers to quickly test the functionality and appearance of the product with the smallest investment cost, which is more suitable for alleviating the financial pressure of small enterprises in the early stage of their business.

In addition, we provide rapid prototyping and rapid stamping die/tool design and manufacturing services to help customers find difficult-to-process details before mass production and avoid expensive repair costs during mass production.

We provide free stamping technical support services, and have a professional technical team to conduct detailed analysis around product design to help customers find the most reasonable manufacturing plan, optimize product design, and combine multiple manufacturing processes to achieve low-cost and high-efficiency products Production, providing one-stop manufacturing solutions for parts with complex designs.

Contact us now to help you make professional answers to detailed questions such as material selection, manufacturing process, part design, manufacturability feedback, and mass production.

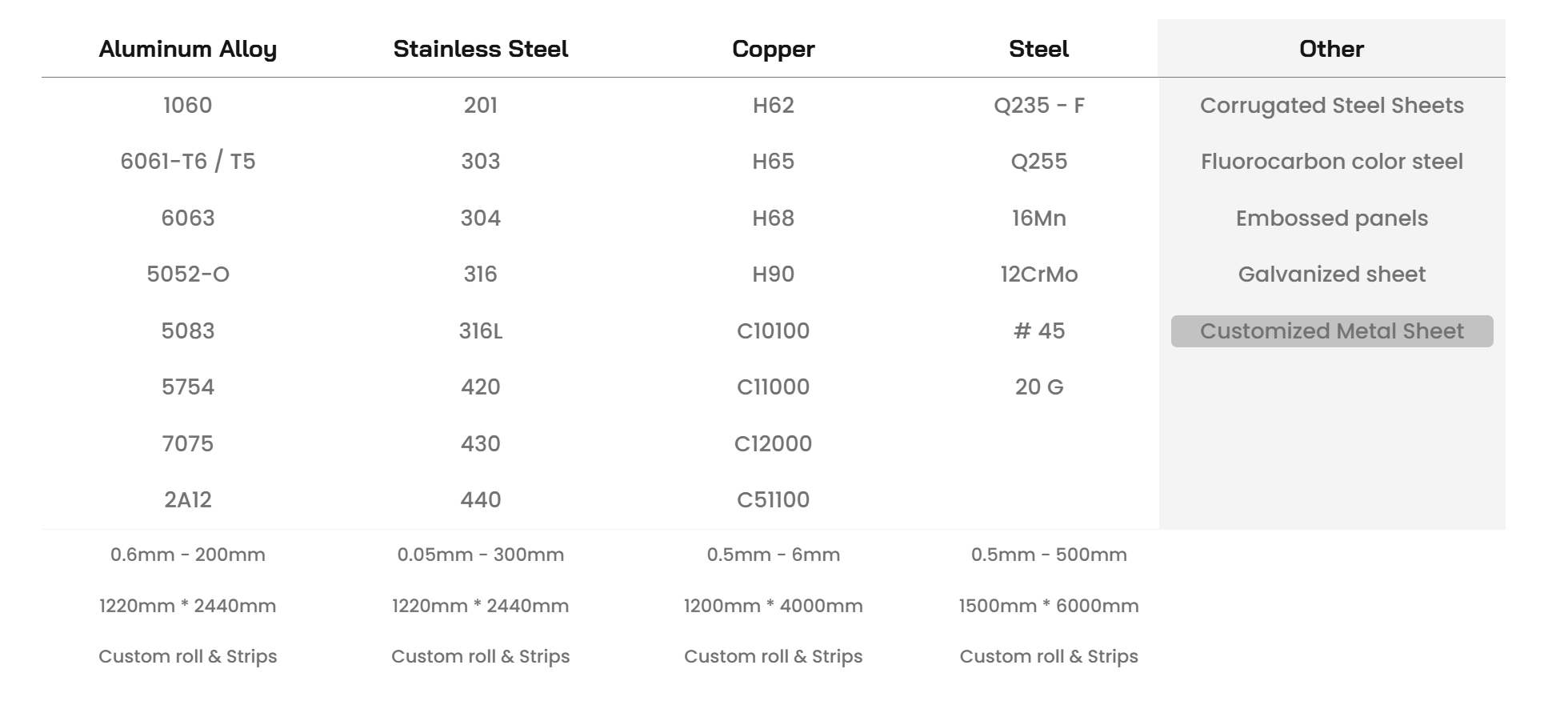

Sheet metal stamping material solutions

Formtechsolution offers a robust stockpile of materials to help your products can get up and running with a quick turnaround.

Within an hour, the metal material is ready for the sheet metal stamping process.

Precision stamping parts surface treatment solution

Reasonable surface treatment of metal parts can improve the durability, corrosion resistance, heat resistance, electrical conductivity and appearance decoration of the material.

-

Mirror polishing

-

Wire drawing

-

Galvanizing

-

Anodizing

-

Black oxide coating

-

Chrome plating

-

Electroplating

-

Powder coating

-

Sandblasting

-

Laser engraving

-

Printing

Application of precision stamping parts

We can meet the most demanding needs and provide customers in various industries with reasonable manufacturing solutions and competitive prices.

Aerospace

Home appliances

Automobile manufacturer

Power accessories

Substation equipment

Electronic Accessories

Communication equipment

Building materials

Building decoration

Renewable energy

Industrial manufacturing

Medical/Medical equipment

Military/defense

Standard parts

Fastener

Construction machinery

Art sculpture

Urban infrastructure

An Overview for :

What is sheet metal stamping processing ?

Metal stamping is a cold forming manufacturing process. The metal plate is deformed or cut instantaneously by pressing the stamping die by the stamping equipment to produce custom metal stamping parts with different shapes.

Metal stamping technology has been widely used. A variety of stamping technologies can be used according to different parts design, but they all require the cooperation of rigid stamping dies and pressure to complete blanking, bending, stamping, Coining, embossing, deep drawing or Manufacturing processes such as scraping metal.

Custom metal stamping services are very suitable for low-cost high-volume manufacturing, high-efficiency manufacturing of tight tolerance parts with complex geometries, complex details, and key shape and surface features.

1. Blanking

It is generally used in the initial stage of custom metal stamping projects. The metal sheet is cut into the part designed 2D shape using a mold to prevent excess materials from affecting the product shape in the subsequent process, and the blanking step can reduce burrs on the part. Risks brought by the stamping process.

It can also be used in the later stage of deep drawing to efficiently cut off excess material.

2. Bending

Bending using custom metal stamping dies is an important step for turning flat (blank) plates into three-dimensional parts, which can be bent and folded quickly and accurately. In the bending process, cracks are very easy to appear. It is necessary to pay great attention to the yield strength of the material and the direction of the internal structure of the material, and perform stamping and bending reasonably.

3. Stamping holes:

Use molds to create high-precision hole designs on metal plates in batches, with a minimum error of ±0.02mm and keep the material cut smooth.

4. Deep drawing:

In order to form the multi-curved surface of the material, we need to use deep drawing stamping to press the metal plate into the mold under pressure to quickly form irregular shapes such as multi-curved surfaces. In this process, the excess material will be used by the mold. Fix it first, and cooperate with lubricating oil to quickly deform the metal sheet.

5. Coining:

Relying on strong pressure to press the mold on the material, the surface of the product is printed with complex patterns or text, usually the impression created by embossing to make the concave shape, which requires high hardness produced by the mold after heat treatment. Similar to the pattern on a coin.

6. Flanging:

Usually, the material is folded by 90° to become the flanging, which requires the material to have excellent yield strength, and the gap size after the folding should be set reasonably to prevent the material from cracking after the extreme stamping and flanging. It is generally used for metal such as tableware. The edges of the container prevent sharp materials from cutting the skin and causing injury.

Flanging is usually divided into several steps, firstly bending over 45°, and then flanging according to product design.

More Case Studies

Formtechsolution actively helps customers from design and prototype to mass production of high quality sheet metal fabrication services.

Custom Stainless Steel Water Tanks

Custom Stainless Steel Water Tanks

Custom Stainless Steel Water Tanks

Custom Stainless Steel Water Tanks

Custom Stainless Steel Water Tanks